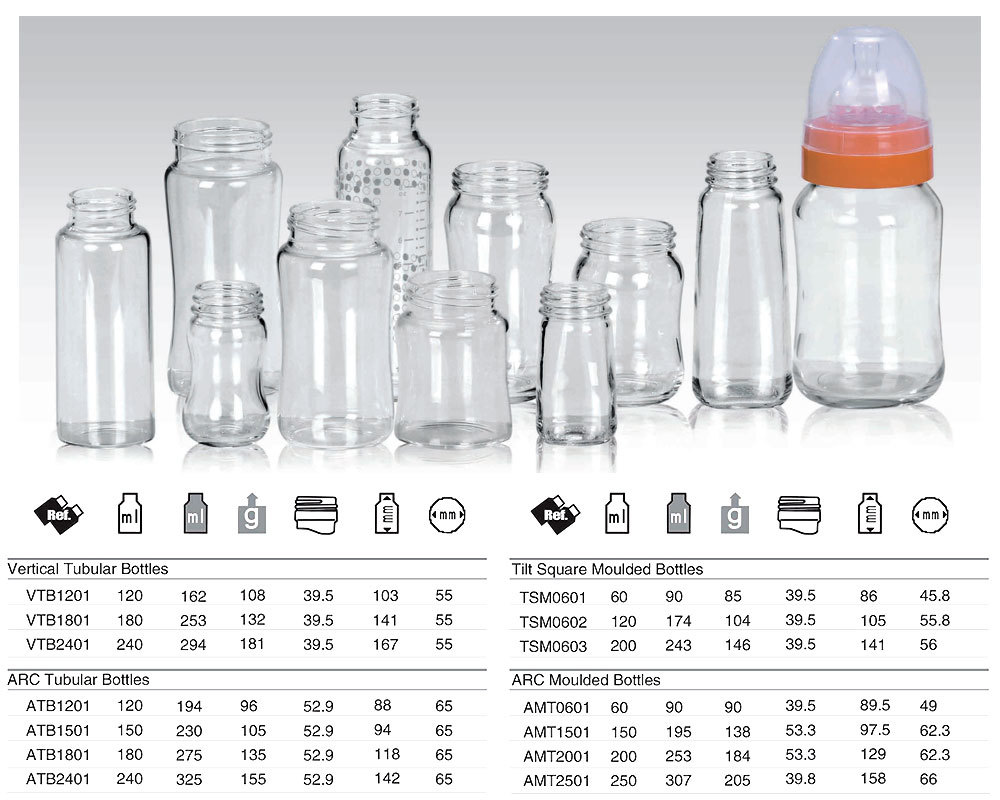

Baby Feeding Bottles

Subcategory:

Food & Beverage bottles and others

Baby Feeding Bottles

Glass is the trusted and proven packaging for health, taste and the environment. It is also the only widely-used food packaging granted the FDA status of “GRAS” or generally recognized as safe – the highest standard.

Facts

Glass is 100% recyclable and can be recycled endlessly without loss in quality or purity.

Legislation such as container deposit measures will further enhance the benefits associated with glass packaging.

80% of the glass that is recovered is made into new glass products.

A glass container can go from a recycling bin to a store shelf in as little as 30 days. An estimated 80% of recovered glass containers are made into new glass bottles.

Glass is nonporous and impermeable, so there are no interactions between glass packaging and products to affect the flavor of food and beverages. No nasty after taste - ever.

Glass has an almost zero rate of chemical interactions, ensuring that the products inside a glass bottle keep their strength, aroma, and flavor.

When consumers choose foods or beverages that are packaged in glass, they avoid potential risks while enjoying a number of benefits.

Advantage

Our company realizes GMP clean production, complete product series, one-stop supply, and has become the Asia's largest and one of the world top three suppliers of pharmaceutical glass packaging materials

1. Our company produces and supplies all pharmaceutical glass packaging materials under the norms of CFDA / ISO and the requirements specified in the current version of EP and USP.

2. Our products are exported to nearly 92 countries and regions, with the annual export scale of around 200 million USD.

3. It has successively passed relevant system certifications, including ISO15378, ISO9001, ISO14001, ISO45001, FSSC22000.

The pharmaceutical glass we produce almost covers the mainstream product types and specifications required in the market. At the same time, we also produce butyl rubber plugs for injection and related supporting caps.

Certificate

Quality Control

Drastically develop quality certification of ISO9001 quality management system and ISO14001 environmental standard, to form a complete rigorous quality assurance system in the enterprise to meet external and international standards into line. On February 19, 1998, we obtained ISO9002: 94 quality system certification. Passed ISO9001: 2000 quality management system certification On August 25, 2003, and ISO14001: 2000 standard on August 25, 2003.

The company has established a sound market services system, through market services, work to effectively master the understanding of the needs of different customers, to grasp the pulse of the market and maximize the elimination of customer complaints. The implementation of the customer complaints on file system is responsible for each of the customer complaints should have special staff in the end, to achieve the implementation of the rate of customer complaints to 100%.

Equipment

Food & Beverage bottles and others

keyword:

Baby Feeding Bottles

Related Accessories

Amber Glass Containers

-

Light Weight Alpha Amber Glass

Full range of Alpha light amber glass bottles for syrup is with similar shape design and same neck finish design, and clear color in same format is available, and we produce and supply their accessories like CRC cap and plastic & al-cap with tamper evidence ring.

-

Amber Dropper Bottle

Essential oil bottle is almost the most complete product series of our company with the widest color coverage. There are five colors and hundred of sizes. We believe that there will always be one that meets your needs.

-

Amber Moulded Vials for Injection

Glass containers for pharmaceutical use are glass articles intended to come into direct contact with pharmaceutical preparations, so its stable hydrolytic resistance is very important, ours meet all requirements specified in the latest version of norm of CFDA YBB, USP, EP.

-

Amber Boston Round Bottles

We produce and supplie a full range of Boston bottles, their neck finish complies with GPI400, there are five colors series available, and the quality requirements such as heavy metal content and leachable meet the requirements in US and Europen market.

-

Amber Glass Bottles for Syrup

Glass containers are commonly made with a combination of various oxides or oxygen-based compounds and are commonly referred to as “soda-lime” glass. The combining of raw materials, including sand, soda ash, limestone and cullet, creates glass containers that are durable, strong, impermeable, easily shaped, and inexpensive. The proportion of raw materials is based on availability, chemical and physical consistency, sizing, purity and cost. The goal is to use the most economical and high-quality raw materials available. Some oxides will form glass without adding any other elements and are known as network formers. The most common of these is silica (SiO2).

-

Amber Tablet Bottles with Wide Mouth

Tablet bottles are mainly used to contain nutritional supplements, tablets and capsules, and are suitable for containing products that need to be protected from light.

Black Bottles

-

Black Dropper Bottle

Including: dropper bottles, cream jars, boston round bottles, cannabis bottles, perfume bottles. Aailable size: from 5ml to 200ml. Glass is made from all-natural sustainable raw materials. It is the preferred packaging for consumers’ concerned about their health and the environment. Consumers prefer glass packaging for preserving a product’s taste or flavor and maintaining the integrity or healthiness of foods and beverages. Glass is the only widely-used packaging material considered “GRAS” or “generally recognized as safe” by the U.S. Food and Drug Administration. It’s also 100% recyclable and can be reused endlessly with no loss in quality or purity.

-

Black Cream Jar

Available Sizes Range: from 15ml to 100ml, including cream Jar, Canabis Jars. Glass is made from all-natural sustainable raw materials. It is the preferred packaging for consumers’ concerned about their health and the environment. Consumers prefer glass packaging for preserving a product’s taste or flavor and maintaining the integrity or healthiness of foods and beverages. Glass is the only widely-used packaging material considered “GRAS” or “generally recognized as safe” by the U.S. Food and Drug Administration. It’s also 100% recyclable and can be reused endlessly with no loss in quality or purity.

-

Black Nailpolish Bottles

Some Nail Polish Bottle need to be personalized in design, which can be considered black glass to produce, compared with the cost of color spraying on clear bottle can be reduced by 40-50%. Aailable size: as you want.

Cosmetic Bottles

-

Coated Bottles in different colors

In the field of cosmetic packaging, some glass bottle packaging needs to be more textured, nothing more than spraying or frosting, or bronzing. At present, frosting has the lowest cost, and frosting will not cause harm to the product. It is through pickling to make the outer surface of the glass bottle even and rough, a bit like a matt feeling.The spraying cost is almost same or more than bottle itself, the bronzing cost will be much more.

-

Frosted Glass Bottles

In the field of cosmetic packaging, some glass bottle packaging needs to be more textured, nothing more than spraying or frosting, or bronzing. At present, frosting has the lowest cost, and frosting will not cause harm to the product. It is through pickling to make the outer surface of the glass bottle even and rough, a bit like a matt feeling.

-

Cream Jars in five colors

Available Sizes Range: from 15ml to 270ml, including Cream Jars, Canabis Jars, Candle Jars, Food Jars. Glass is made from all-natural sustainable raw materials. It is the preferred packaging for consumers’ concerned about their health and the environment. Consumers prefer glass packaging for preserving a product’s taste or flavor and maintaining the integrity or healthiness of foods and beverages. Glass is the only widely-used packaging material considered “GRAS” or “generally recognized as safe” by the U.S. Food and Drug Administration. It’s also 100% recyclable and can be reused endlessly with no loss in quality or purity.

-

Nail Polish Bottles

Glass is the trusted and proven packaging for health, taste and the environment. It is also the only widely-used food packaging granted the FDA status of “GRAS” or generally recognized as safe – the highest standard.

-

Essential Oil Bottles in four colors

Essential oil bottle is almost the most complete product series of our company with the widest color coverage. There are five colors and hundred of sizes. We believe that there will always be one that meets your needs.

-

Perfume Bottles

Available Sizes Range: from 5ml to 100ml. Glass is made from all-natural sustainable raw materials. It is the preferred packaging for consumers’ concerned about their health and the environment. Consumers prefer glass packaging for preserving a product’s taste or flavor and maintaining the integrity or healthiness of foods and beverages. Glass is the only widely-used packaging material considered “GRAS” or “generally recognized as safe” by the U.S. Food and Drug Administration. It’s also 100% recyclable and can be reused endlessly with no loss in quality or purity.

Different Colors Boston Round Bottles

-

Green Boston round bottles

Including: dropper bottles, cream jars, boston round bottles, cannabis bottles, tablet bottles. Available colors: amber, clear, green, blue and black.

-

Blue Boston round bottles

In the field of cosmetic packaging, some glass bottle packaging needs to be more textured, nothing more than spraying or frosting, or bronzing. At present, frosting has the lowest cost, and frosting will not cause harm to the product. It is through pickling to make the outer surface of the glass bottle even and rough, a bit like a matt feeling.The spraying cost is almost same or more than bottle itself, the bronzing cost will be much more.

-

Boston Round Bottles in four colors

In the field of cosmetic packaging, some glass bottle packaging needs to be more textured, nothing more than spraying or frosting, or bronzing. At present, frosting has the lowest cost, and frosting will not cause harm to the product. It is through pickling to make the outer surface of the glass bottle even and rough, a bit like a matt feeling.The spraying cost is almost same or more than bottle itself, the bronzing cost will be much more.

Different Colors Dropper Bottles

Tablet Bottles

-

Tablet Bottles in four colors

Tablet bottles are mainly used to contain nutritional supplements, tablets and capsules, in addition, according to the personalized needs of customers, we produce and provide a variety of color choices, and the glass products have more texture.

-

Amber Glass Packer

Amber Glass Packers are mainly used to contain nutritional supplements, tablets and capsules, and are suitable for containing products that need to be protected from ultraviolet light.

-

J-CAP Glass Bottle for Tablet

Suitable for pharmaceutical pills and dietary supplement applications, the bottle is colored to reduce the exposure to light.

Cream Glass Jar in different Colors

-

High Quality Clear Cosmetic Glass Cream Jar/Bottle Empty Glass Bottle 15ml

Packing: Carton,Pallet; Delivery:By sea

-

Glass cosmetic bottle cylinder glass jar cream glass jar 30ml 30BGZ/30ZGZ/30LGZ/30HGZ

Packing: Carton,Pallet; Delivery:By sea

-

Cream Jars in five colors

Available Sizes Range: from 15cc to 120cc, including cream Jar, Canabis Jars. Re: European Council Directive 94/62/EC-Article 11 and Meet the requirements specified in TPCH from US.

-

Frosted Jars

In the field of cosmetic packaging, some glass bottle packaging needs to be more textured, nothing more than spraying or frosting, or bronzing. At present, frosting has the lowest cost, and frosting will not cause harm to the product. It is through pickling to make the outer surface of the glass bottle even and rough, a bit like a matt feeling.The spraying cost is almost same or more than bottle itself, the bronzing cost will be much more.

Moulded Injection vial, type I,II,III

-

Moulded Injection Vials Type I,II,III

Available Format: sizes from 5ml to 100ml, meet all requirements specified in the latest version of norm of CFDA YBB, USP, EP. Color: Clear and Amber; Glass type: made of sodalime glass or borosilicate glass, including type I, II, III, always is available in stock.

-

Amber Moulded Vials for Injection

Available Format: type I [CFDA YBB, USP, EP], as alternative of tubular glass vial Color: Clear and Amber; Glass type: Borosilicate glass type I. Sizes Range: 6-30ml. Glass containers for pharmaceutical use Glass containers for pharmaceutical use are glass articles intended to come into direct contact with pharmaceutical preparations.

-

Light Weight Type I Moulded Vial (Lyo-Vial)

Available Format: type I [CFDA YBB, USP, EP], as alternative of tubular glass vial Color: Clear and Amber; Glass type: Borosilicate glass type I. Sizes Range: 6-30ml. Glass containers for pharmaceutical use Glass containers for pharmaceutical use are glass articles intended to come into direct contact with pharmaceutical preparations.

Food & Beverage bottles and others

-

Cannabis Bottles in Different Colors

In recent years, it has become particularly popular to have a vertical bottle shape on the inside of the bottle, which is usually used to hold cannabis and eye cream products.

-

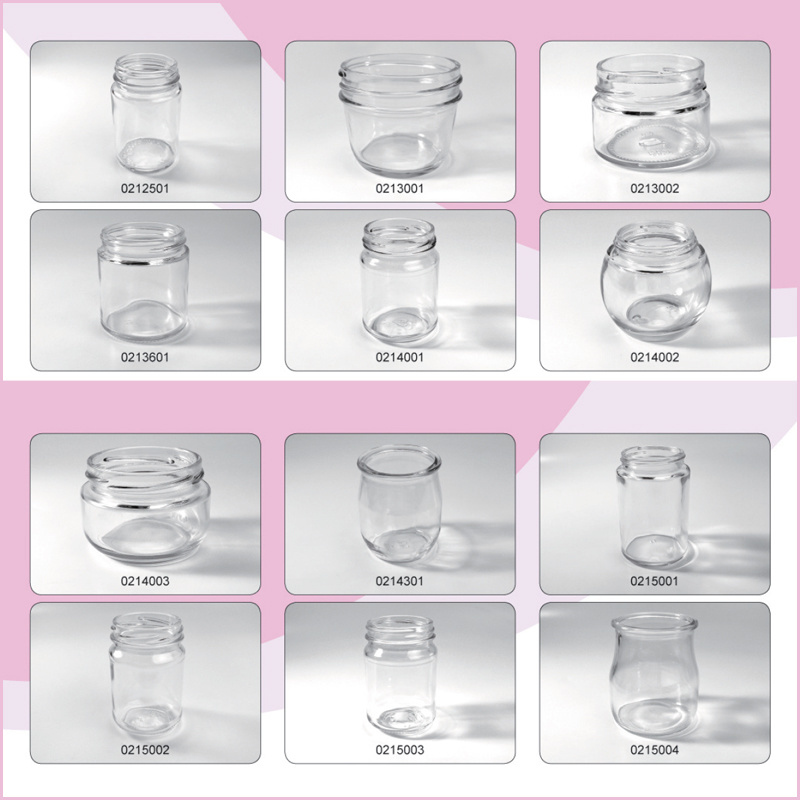

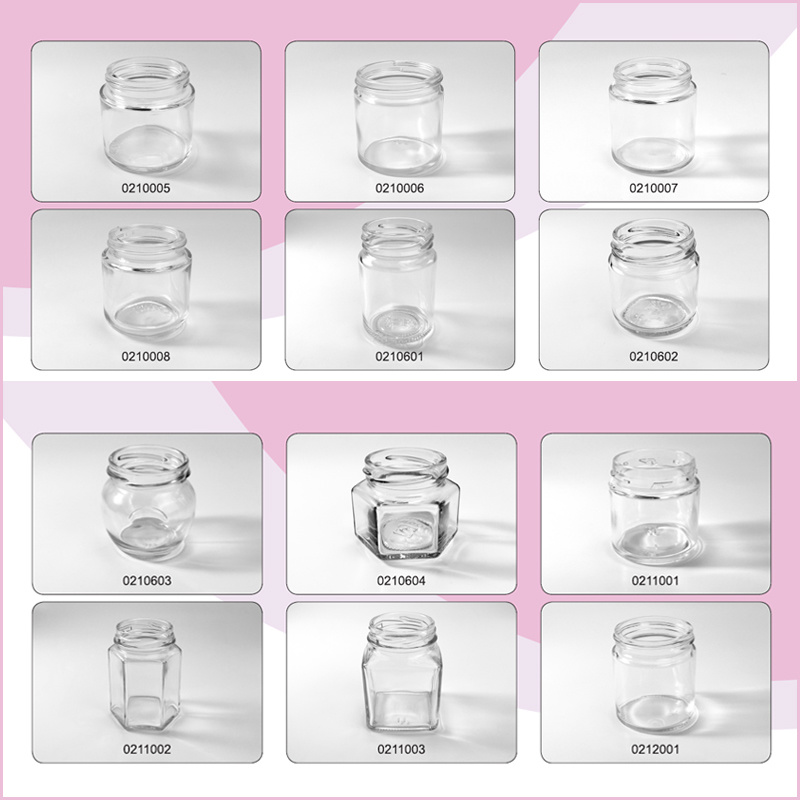

Different Food Glass Jars

We have nearly 200items of food glass jars and beverage glass containers in our inventory, perhaps there is one that meets your requirement.

-

Clear Glass Jars

We have nearly 200items of food glass jars and beverage glass containers in our inventory, perhaps there is one that meets your requirement.

-

Food and Beverage Glass Containers

Release of Arsenic as per the current version of EP and USP We certify that Arsenic is not intentionally added as components in the batch composition with which we manufacture our glass for containers. If very slight traces are present in the glass, they come from impurities contained in the raw materials of mineral origin used for the preparation.

-

Baby Feeding Bottles

Glass is the trusted and proven packaging for health, taste and the environment. It is also the only widely-used food packaging granted the FDA status of “GRAS” or generally recognized as safe – the highest standard.

Infusion Bottles, type I & II

-

Clear Infusion Bottles Type I

Normative type bottles with 32mm Neck finish Size: 50ml to 500ml, Glass type I, II. Contrast media, like Iohexol, Iopamidol injection, Multihance, Metronidazole file, ofloxacin,High concentrations of sodium chloride, agnesium sulfate, potassium chloride injection, and so on.

-

Clear Infusion Bottles Type II

Normative type bottles with 32mm Neck finish Size: 50ml to 500ml, Glass type I, II. Contrast media, like Iohexol, Iopamidol injection, Multihance, Metronidazole file, ofloxacin,High concentrations of sodium chloride, agnesium sulfate, potassium chloride injection, and so on.

-

Amber Infusion Glass Bottles

Normative type bottles with 32mm Neck finish Type I amber infusion bottle available sizes: 50ml and 100ml